Conducting a prompt scientific soot, silt and smoke damage analysis on the equipment ensures that only those items exhibiting potentially harmful corrosive contamination will be decontaminated and restored.

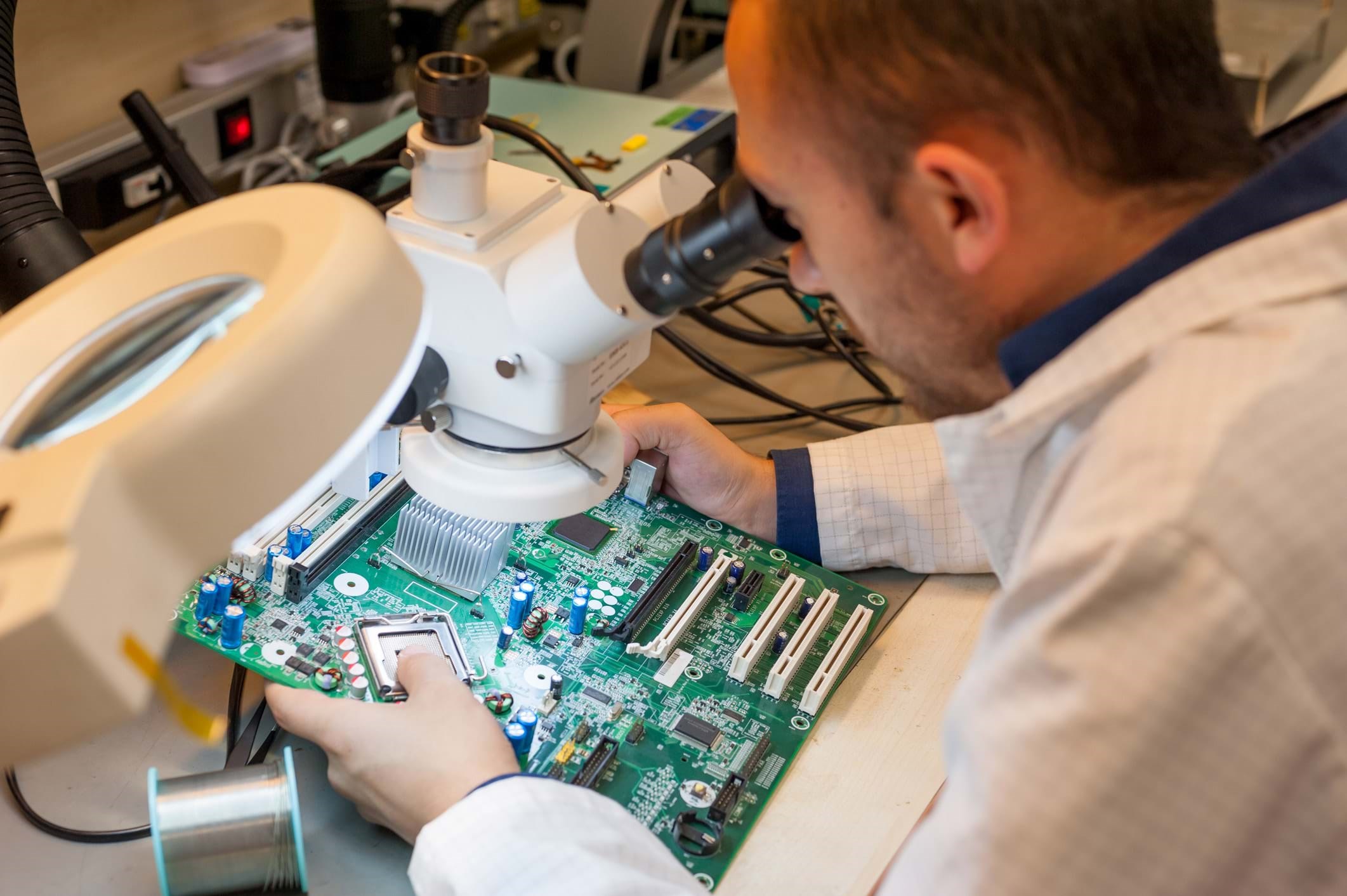

Following damages to a company’s critical equipment and systems, stakeholders need to rely on a team of technical experts who are committed to the full restoration and recovery of all impacted machines. To ensure full recovery of the damaged equipment, it is critically important that all the potentially affected items are properly inspected to gain an understanding of what equipment is showing effects of contamination, what pieces may have been spared, the overall levels of contamination, as well as any industry or manufacturer cleanliness standards that the recovery process will have to adhere to.

AREPA utilizes laboratories around the globe for contamination analysis and our team of dedicated project managers work with clients to communicate the results so that necessary steps are taken to proceed with restoration, repair & recertification or in some cases where contamination is substantial, to fully replace the equipment.