Often a byproduct of construction or present in most of today’s manufacturing facilities, concrete, gypsum, wood and other building materials can easily cover all horizontal surfaces. Add in humid conditions and the dust and powder is now coating most surfaces. Ventilation systems present in production plants can make the contamination worse by spreading it throughout a facility. The risk caused by this type of damage is primarily reduced by cooling of electronic and electric parts. In a case of heavy dust contamination, heating may result in fire.

The common impact to current-carrying equipment and systems exposed to dust and powder is electrical short-circuits or arcing, since some types of dust are capable of conducting electricity. Secondary damage can also be an issue. Powder damage from fire extinguishers frequently cause secondary damage when used to extinguish the fire, or because they are used in acts of vandalism. The powder is a hygroscopic product, which attracts humidity to the surface and can result in the corrosion of metal surfaces.

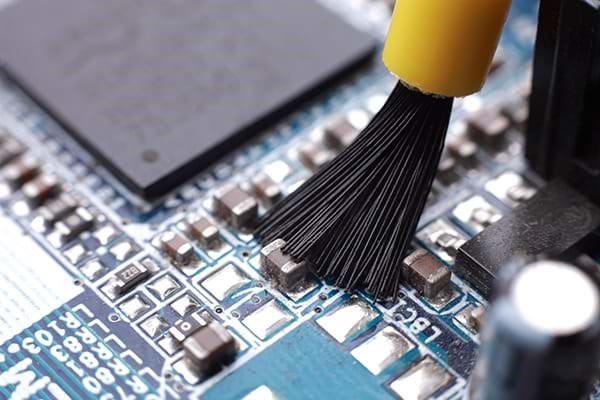

Secondary damage caused by dust and powder damage is an often-neglected cause of damage on movable parts such as ball bearings and axles. Fine-grained dust can act as a polishing powder and shorten the lifetime on moving parts in the equipment. AREPA equipment specialists are experts in evaluating equipment that has been impacted by Dust and Powder damage. While each project is unique, utilizing our proven techniques for preserving and stabilizing equipment, scientific contamination analyses, along with expert dry- and wet-cleaning processes, can greatly reduce long-term equipment damages, business interruption and lost production time.